Objective and Scope

Within an oxygen concentrator, delivering the generated oxygen to a patient safely and effectively requires precise control. This is the essential role of the pressure regulator, a small but fundamentally important component that acts as the final gatekeeper. It steps down the high internal pressure of the machine to a low, stable output pressure suitable for therapeutic use. For the service professional, a comprehensive understanding of how this device works is crucial for accurate calibration and troubleshooting.

Component Architecture and Specifications

- Function: The regulator’s primary function is to take the variable inlet pressure from the concentrator’s accumulator tank, which can be anywhere from 20 to 30 PSI, and reduce it to a constant, low outlet pressure, typically around 8 PSI.

- External Features: The device has an inlet port, an outlet port, and an adjustment mechanism. This adjustment can take several forms, from a simple knob to a screw requiring an Allen key or a specialized triangular head screwdriver.

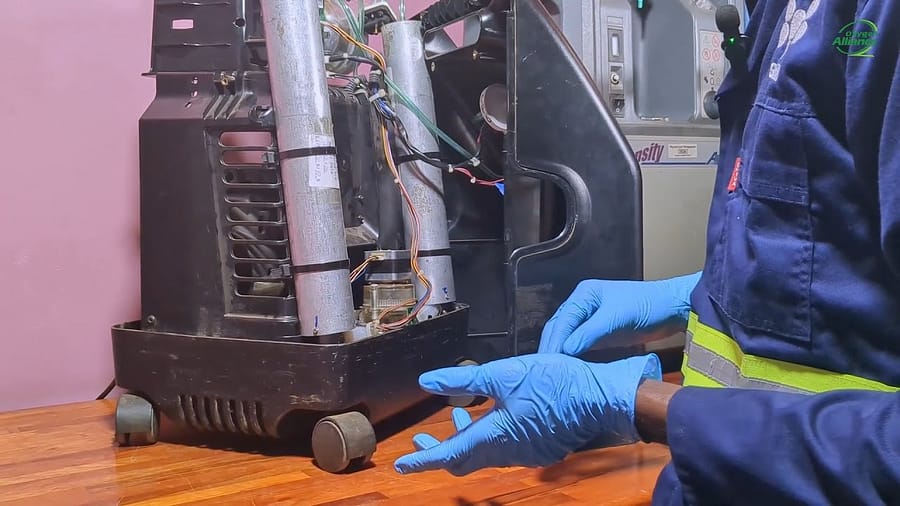

Teardown and Internal Components

Safety Warning As per industry best practice, ensure the oxygen concentrator is disconnected from the mains power source and the pneumatic system is fully depressurized before performing any disassembly of pressurized components.

A pressure regulator contains a sophisticated internal mechanism designed to balance forces with remarkable precision. Unscrewing the top bonnet exposes the internal components.

- An adjustment screw

- A large loading spring

- A flexible diaphragm unit

Principle of Operation: The Equilibrium of Forces

These parts work together in a delicate equilibrium.

- When the adjustment knob is turned, it changes the compression of the loading spring, which in turn applies a specific downward force onto the diaphragm.

- This force opens a valve, allowing the high-pressure gas to flow into a low-pressure chamber.

- As this chamber fills, the gas exerts an upward pressure on the diaphragm, opposing the force of the spring.

- The system reaches equilibrium when these two forces balance, holding the valve open just enough to maintain the exact set output pressure.

Service and Calibration Implications

When a concentrator is failing to maintain a stable output pressure, a service professional can confidently assess whether the issue lies with the regulator.

- Prerequisite for Adjustment: Before making any adjustment, the system must be free of leaks, as a leak will prevent the low-pressure chamber from reaching the required balancing pressure.

- Conclusion: This expertise allows a technician to calibrate a regulator with precision and confidence, ensuring every machine serviced delivers oxygen not just at the right purity, but at the right pressure as well.

Video Resource

To provide a clear, visual exploration of this essential component, a video has been created that details a complete teardown of a pressure regulator. The presentation explains the function of each internal part and demonstrates how they work together to control pressure.

Watch the full teardown video here: