Objective and Scope

The performance of an oxygen concentrator is directly dependent on the condition of the zeolite within its sieve beds. Over time, this material degrades, reducing its capacity to absorb nitrogen and causing a decline in oxygen purity. For the highly skilled technician, refilling the existing sieve bed canister with fresh zeolite is a cost-effective and sustainable alternative to a full component replacement.

This document outlines the protocol for refilling a sieve bed from a Devilbiss 525 concentrator using the “snowfall method,” an advanced procedure that requires precision and patience.

Prerequisites and Safety Warnings

Successful execution of this procedure is dependent on strict adherence to the following environmental and safety protocols.

- Environmental Control: The work area’s relative humidity must be below 50%. This is a critical check to prevent moisture from contaminating the new, highly absorbent zeolite material.

- Mechanical Hazard: The sieve bed canister contains a compressed spring. Exercise extreme caution during disassembly to safely manage the release of this spring.

- Skill Level: This is an advanced restoration procedure that goes beyond simple component swapping and requires a high degree of technical skill.

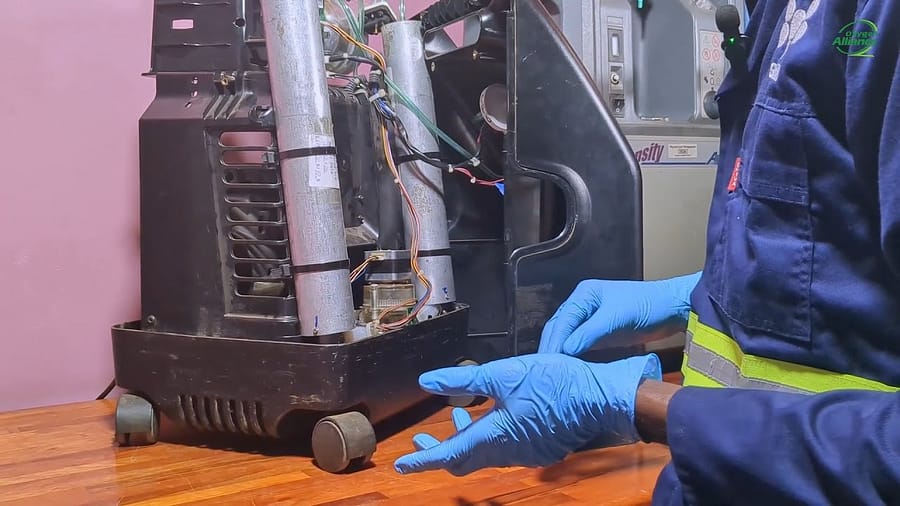

Sieve Bed Refilling Procedure

Disassembly

- Make a precise cut through the canister body using a hacksaw to prepare for opening.

- Carefully separate the canister sections, controlling the release of the internal compressed spring.

- Discard all of the old, degraded zeolite material from the canister.

Canister Preparation

- Meticulously smooth the cut edge of the canister using files and sandpaper. This step is critical for creating a perfect seal during reassembly.

Refilling via the Snowfall Method

- Using a specialized “snowfall tool,” pour the new zeolite into the canister. Employ a gentle, circular motion to ensure the material distributes evenly and compacts densely for optimal performance.

- Continuously measure the zeolite fill level to ensure it matches the original factory fill height.

Reassembly and Sealing

- Reinsert the internal spring and end cap assembly into the canister.

- Securely seal the canister by drilling a series of holes and driving in self-tapping screws.

Mandatory Post-Service Validation

Before the refilled sieve bed can be returned to service, a full pressure and leak test must be performed. This final step is mandatory to confirm the integrity of the new seals and the overall viability of the restoration. Mastering this procedure allows a technician to extend equipment life, reduce repair costs, and restore a concentrator’s performance to factory standards.

Video Reference

A comprehensive, step-by-step video tutorial has been created to guide technicians through every detail of this advanced procedure, from the initial humidity check to the final pressure test.

Watch the full refilling guide here: