System Overview and Interface

A modern oxygen concentrator like the Canta V5-W-NS is a sophisticated blend of pneumatic systems and electronic controls. For the biomedical technician, a comprehensive, component-level knowledge is the cornerstone of effective service and repair. The Canta V5-W-NS features a user-friendly external interface, which includes a simple power switch, a flow meter, and an LCD control area. This area provides real-time status updates through a series of indicator lights for power, service status, and oxygen purity.

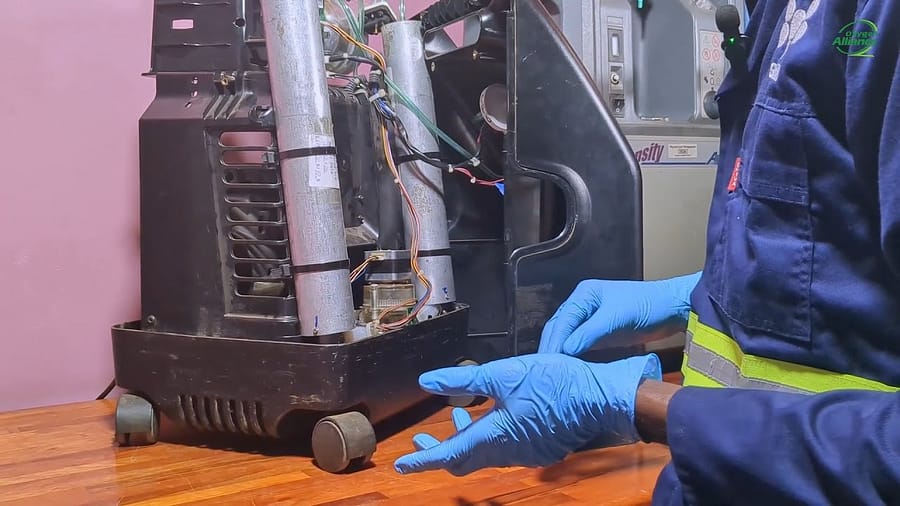

Safety Precautions As per industry best practice, disconnect the device from the mains power source before removing covers for internal service. This guide discusses potential electrical and pneumatic faults. Only qualified technicians should perform diagnostics and repairs on these systems, using appropriate personal protective equipment (PPE) and following all safety protocols.

Pneumatic System Pathway

A full teardown of the machine reveals a densely packed but logically organized interior. The pneumatic pathway is as follows:

- Air enters the unit through a two-stage filtration system.

- The filtered air is then drawn into the compressor.

- The resulting pressurized air is cooled by a heat exchanger.

- A main feed and waste solenoid valve directs the cooled air into one of two molecular sieve beds.

- Inside the beds, the pressure swing absorption process separates nitrogen from the air to produce purified oxygen.

- The purified oxygen is temporarily held in a product tank.

- Before delivery to the patient, the oxygen passes through a final bacterial filter.

Electronic Control and Diagnostic System

Main Control Board

The entire oxygen generation process is managed by a main control board. This board also communicates with the front-facing LCD to display the machine’s status and any diagnostic error codes.

Diagnostic Error Codes

A key feature of the Canta V5-W-NS is its range of specific error codes designed to guide the technician toward the root cause of a problem. Understanding this diagnostic language enables expert-level troubleshooting.

| Error Code | Fault Description | Potential Cause(s) |

| 1 | Overheating issue. | A faulty cooling fan or poor ventilation. |

| 020 | Defective control valve. | An internal fault with the main solenoid valve assembly. |

| 0030 | High pressure. | Blockages within the pneumatic system, such as a kinked tube. |

| 000040 | Low pressure. | Leaks within the pneumatic system or a performance issue with the compressor. |

Export to Sheets

Conclusion: From Fault Code to Resolution

An integrated knowledge of the Canta V5-W-NS systems and its error codes allows a technician to work with confidence and precision. A generic alarm, such as for low purity, becomes the starting point for a structured investigation. This complete system view transforms troubleshooting from a process of elimination into a targeted, intelligent search, allowing for faster and more effective issue resolution.

Video Resource

A comprehensive video guide has been produced to provide a complete visual reference for this machine. The presentation includes a detailed tour of its external and internal components, an explanation of its error codes, and a full disassembly and reassembly procedure.

Watch the full teardown video here: