In many clinical settings, resource efficiency is a primary concern. An oxygen flow splitter is a device born from this need, allowing a single oxygen source to serve multiple patients. While it is a mechanically simple device, its proper function is essential for delivering the correct prescribed flow. For the biomedical professional, understanding the potential points of failure within this straightforward system, such as internal leaks or blockages, is the key to ensuring it operates reliably and safely.

Principle of Operation

An oxygen flow splitter is a resource-efficiency device that allows a single oxygen source to serve multiple patients. At its core, it functions as a passive distribution manifold. It takes a single stream of oxygen and divides it among multiple, independently controlled flow meters, typically five. The internal layout consists of a simple network of tubing that connects a central inlet port to each individual flow meter. Each flow meter has its own adjustment knob, allowing a clinician to set a specific flow rate, usually up to 2 liters per minute, for each patient.

Critical Operational Requirement

Proper function of this device is essential for delivering the correct prescribed flow to all patients.

- Required Action: The total flow rate set on the source oxygen concentrator must exceed the sum of all the flows being drawn from the splitter.

- Rationale: Failure to meet this requirement will result in inadequate oxygen delivery to one or more outlets, compromising patient therapy.

Common Faults and Diagnostics

While mechanically simple, several issues can arise that require service. Understanding these potential points of failure is key to ensuring the device operates reliably.

Leaks

- Potential Causes: Leaks are a common problem and can be caused by cracked flow meter housings, disconnected internal tubing, or degraded O-rings.

Stuck Flow Ball

- Potential Causes: This is a frequent issue, often resulting from an accumulation of dust or moisture inside the flow meter tube.

Blockages

- Potential Causes: The air path can become obstructed by insects or other debris.

Troubleshooting and Maintenance Procedure

A targeted approach based on the reported fault saves valuable diagnostic time.

Diagnostic Logic

- Symptom: A report of “no flow” from a single outlet.

- Potential Causes:

- A disconnected tube leading to that specific flow meter.

- The flow ball is stuck within that meter.

- A blockage exists within that specific channel.

Flow Meter Service

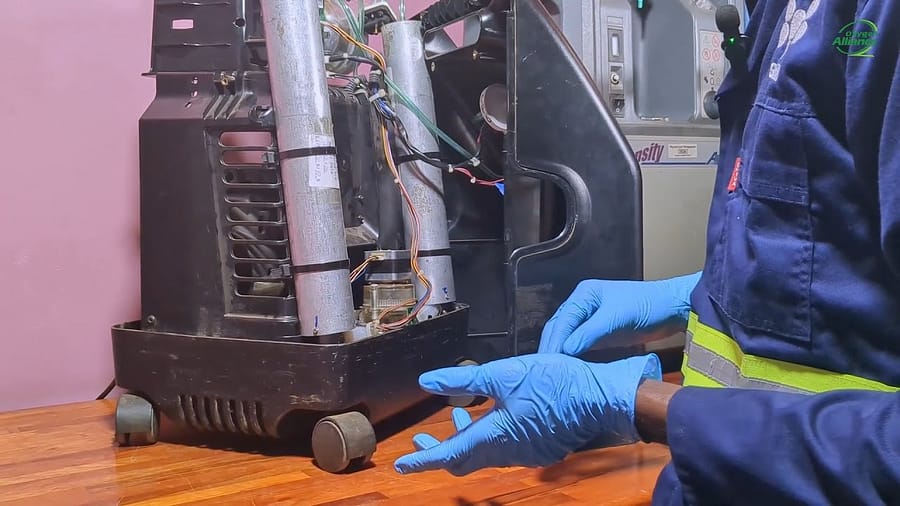

A full teardown gives a technician complete control over the service process. This allows for the restoration of most flow splitters without requiring expensive replacement parts.

- Disassemble the specific flow meter that is malfunctioning.

- Inspect its three critical O-rings for any signs of damage or degradation.

- Clean the interior channel thoroughly to free a stuck ball or remove debris.

- Reassemble the unit correctly, ensuring the inlet and outlet tubes are connected to the proper ports to restore function.

Video Resource

To provide a clear, practical guide to servicing these devices, a video is available that demonstrates the entire process, including a full teardown, an explanation of common faults, and a step-by-step cleaning and reassembly of a flow meter.

Watch the full maintenance video here: