System Overview and User Interface

The Invacare Perfecto oxygen concentrator is a common device in many healthcare environments. For the biomedical technician, a foundational knowledge of its interconnected systems is essential for effective troubleshooting and repair.

The external design features a straightforward user interface. This includes a flow meter with an adjustment knob for setting the prescribed output and a simple LED indicator panel to show the machine’s operational status.

Internal Systems Analysis

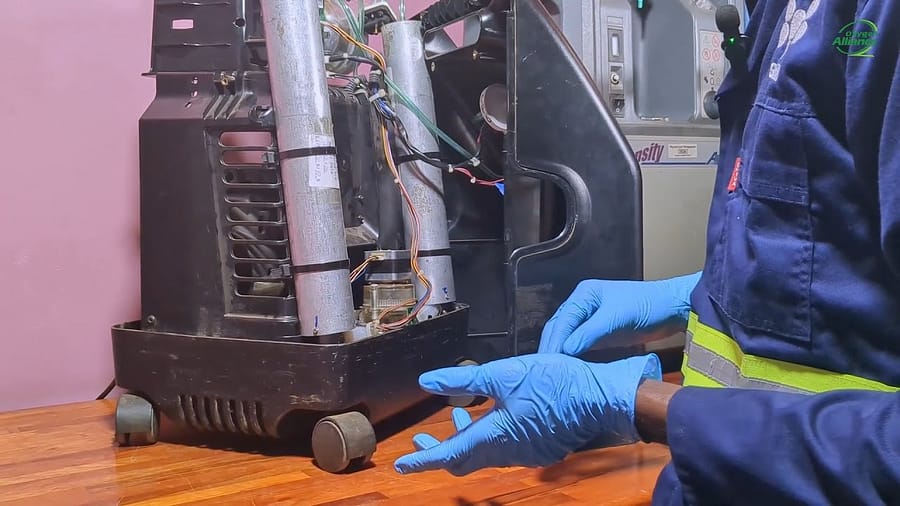

A complete teardown of the Invacare Perfecto reveals a logical and modular construction designed for function. Mastering the architecture of these internal systems is a fundamental requirement for any service event.

Pneumatic Pathway

The pneumatic system is responsible for air intake, purification, and delivery. The pathway proceeds as follows:

- Intake and Compression: Ambient air is drawn through filters and into a Thomas brand compressor, which pressurizes the air to 21 PSI.

- Cooling: The pressurized air is immediately cooled by a heat exchanger to optimize the purification process.

- Oxygen Generation: A pilot-operated four-way solenoid valve directs the cooled air into one of two sieve beds. These beds are filled with a zeolite material that absorbs nitrogen from the air.

- Storage and Regulation: The resulting concentrated oxygen is held in a product tank. Before being delivered to the user, the oxygen is regulated down to a pressure of 5 PSI.

Electrical and Control System

A central printed circuit board (PCB) controls the entire process. It manages the timing of the solenoid valves that control airflow between the sieve beds. The PCB monitors system pressure via a transducer and reads data from a ceramic zirconia oxygen sensor to ensure purity meets specifications. A transformer steps down the main voltage to provide the correct power for these sensitive electronic components.

Service Procedures: Disassembly and Troubleshooting

Approaching a service call with a complete understanding of the unit’s architecture allows for greater speed and precision in diagnostics.

Safety Precautions

As per industry best practice, always disconnect the device from the power source before service. Be aware that oxygen concentrators create an oxygen-enriched environment; adhere to all fire safety protocols. Post-service performance verification must be conducted using a calibrated oxygen analyzer to ensure output purity meets manufacturer specifications.

Required Tools and Preparation

Mastering the correct disassembly procedure ensures that any part can be accessed without causing unintended damage. Specific tools required for service include:

- Torx screwdrivers

- A 16mm spanner for the compressor bolts

Common Troubleshooting Checkpoints

When a fault is indicated by the control board, a technician can trace the issue to a specific component. Key areas to investigate during a diagnostic assessment include:

- The compressor’s start capacitor

- The pressure equalization valve

- All physical connections on the printed circuit board

Concluding Remarks and Video Resource

This comprehensive knowledge of the Invacare Perfecto elevates a technician’s capability, streamlining workflow and preserving the integrity of the machine. To provide a clear, practical reference for these procedures, a full video guide has been created detailing the complete teardown and reassembly of the concentrator. This visual demonstration will solidify your understanding and serve as a valuable resource.

Watch the full teardown and assembly video here: