A Biomedical Engineer’s Guide to Servicing the Thomas 2660 Compressor

Introduction

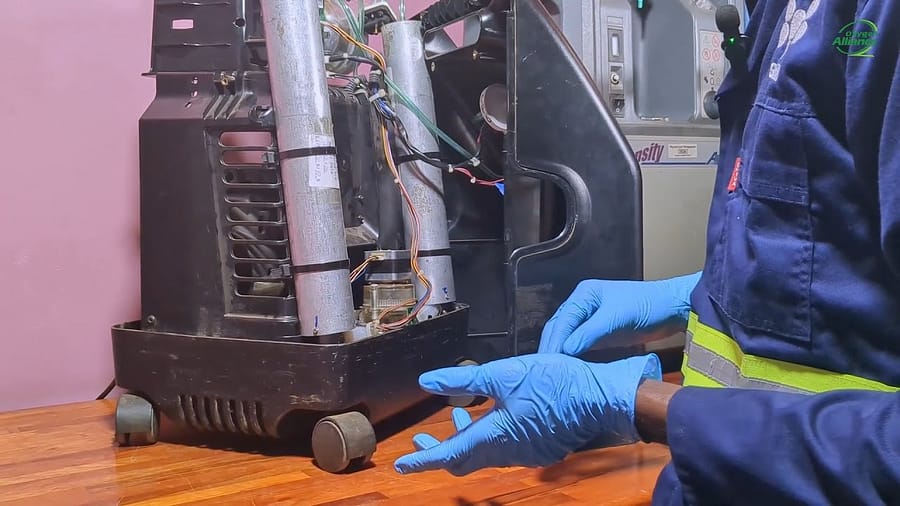

The Thomas 2660 compressor is a workhorse in many medical oxygen concentrators, valued for its durability and performance. Proper maintenance is critical to ensure it operates efficiently and reliably, preventing premature failure and ensuring patient safety. This guide provides a detailed, step-by-step walkthrough for biomedical engineers and technicians on how to fully service the Thomas 2660 compressor.

Key Servicing Procedures

Our accompanying video provides a complete visual guide to the disassembly, cleaning, and reassembly of the compressor. The key procedures covered are essential for restoring the unit to optimal working condition.

- Initial Inspection: Assessing the external condition of the compressor, checking for any visible damage or leaks before disassembly.

- Cup Seal Replacement: The cup seal is a critical wear component. We demonstrate the correct procedure for removing the old seal and installing a new one to ensure a proper pressure seal.

- Cylinder Sleeve and Piston Cleaning: Over time, residue can build up on the cylinder sleeve and piston. This section covers the safe removal and meticulous cleaning of these parts to ensure smooth, unrestricted motion.

- Valve Plate and Gasket Inspection: The valve plates and gaskets are crucial for maintaining pressure. We show how to inspect them for warping or damage and ensure correct re-installation.

Ensuring Long-Term Reliability

Following a structured servicing protocol not only resolves current issues but also significantly extends the operational lifespan of the compressor. This preventative maintenance is a cornerstone of effective medical equipment management.

Watch the full guide here: How to Service a Thomas 2660 Compressor