Maximizing Oxygen Purity; Essential Aspects for Performance of Oxygen Concentrators

In the pursuit of top-notch medical care and patient well-being, having a deep understanding of the intricacies of oxygen concentrator technology goes beyond just a technical necessity – it’s a crucial lifeline. Our recent webinar delved into the core factors that shape oxygen production in these devices shedding light on their importance for healthcare professionals, engineers, and users. Mastering these aspects isn’t just about operational efficiency; it’s about making a difference in saving lives with every breath.

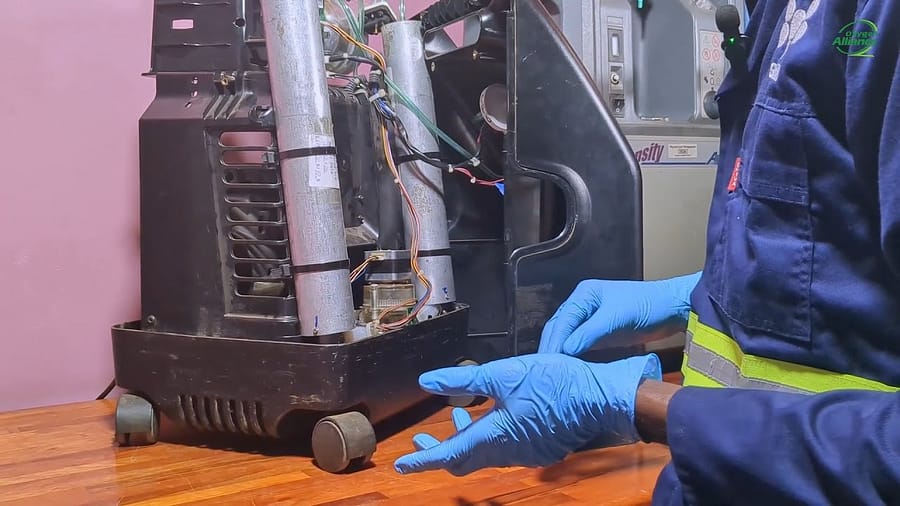

The Significance of Maintenance

At the core of an oxygen concentrator’s effectiveness lies thorough maintenance. This fundamental truth resonates across both engineering and healthcare sectors; well-kept equipment performs better and has a longer lifespan. Whether it involves changing filters, inspecting for leaks, or ensuring all parts are operating optimally, routine maintenance isn’t about averting downtime; it’s about guaranteeing the purity of oxygen provided to those who depend on it.

The Impact of Climate

Environmental conditions play a substantial role than often assumed in determining the efficiency of oxygen concentrators. High temperature, levels of humidity, and poor air quality directly affect the ability of the device to produce high purity oxygen.

In conditions, device performance may be impacted and humidity could introduce moisture that affects the crucial adsorption process for oxygen concentration. Managing these variables is key to ensuring the best possible performance of the device.

Exploring the Core Technology; Pressure Swing Adsorption(PSA)

Pressure Swing Adsorption(PSA) technology lies at the core of oxygen concentrators. This technique relies on separating gases using adsorbent materials under different pressures enabling these devices to efficiently extract oxygen from the air. Understanding the nuances of PSA technology is vital for individuals involved in maintaining, designing, or using oxygen concentrators as it directly influences the purity of generated oxygen.

User Engagement

The way a user interacts with a device can significantly impact its performance. Improper positioning, incorrect flow setting and neglecting routine maintenance are all user-driven factors that can negatively affect oxygen generation. . Educating users on optimal device handling practices is just as crucial, as understanding the technology itself to maintain top-quality oxygen production.

Machine Factors

These are mainly hardware faults that impair the oxygen production in an oxygen concentrator. Leaks lower the system pressure and prevent it from reaching the optimal levels for pressure swing adsorption (PSA). Blockages hinder the air flow. Feed-waste control valve regulates the air intake and exhaust of the sieve beds. If it fails, the concentrator cannot produce high purity oxygen. Used zeolite is another factor. Over time, the zeolite accumulates moisture and loses its capacity to adsorb nitrogen, which affects the oxygen output. Worn-out compressor kits decrease the maximum pressure that the compressor can achieve. A faulty PCB sends incorrect signals to the feed-waste valve. Some PCBs have built-in oxygen sensors that can leak and reduce the purity. Other factors include a damaged pressure regulator and cooling fan.

Advancing Through Innovation and Lifelong Learning

Takeaways from the Oxygen Alliance webinar emphasize how continuous learning and innovation play roles in advancing medical oxygen technology.

As we gain insights into the elements influencing the efficiency of oxygen concentrators, we can make advancements in their design, features, and user training. This doesn’t just improve care but also supports global health efforts, especially in areas with limited resources where access to medical oxygen is a significant issue.

Emergency Preparedness

A key lesson from the webinar stresses the importance of having oxygen concentrators ready for emergencies. Being prepared is crucial not only for individual patient safety but also for broader public health responses. Regular inspections, upkeep, and a good grasp of user factors can ensure that these devices provide life-saving oxygen when it’s most needed.

As we explore the factors impacting oxygen generation in concentrators it becomes evident that a comprehensive approach is vital for optimizing device performance. From the intricacies of PSA technology and the influence of circumstances to the significance of user education and routine maintenance, each aspect plays a crucial role. For healthcare professionals, engineers, and users alike, understanding these factors isn’t about enhancing device effectiveness—it’s about guaranteeing that every breath taken is as clean and safe as possible.

In the changing realm of medical oxygen technology keeping up-to-date attentive and proactive plays a crucial role in achieving success. The valuable information shared during the Oxygen Alliance webinar serves as a basis for individuals aiming to enhance their knowledge of oxygen concentrators leading to advancements in patient care, innovation, and better global health results.