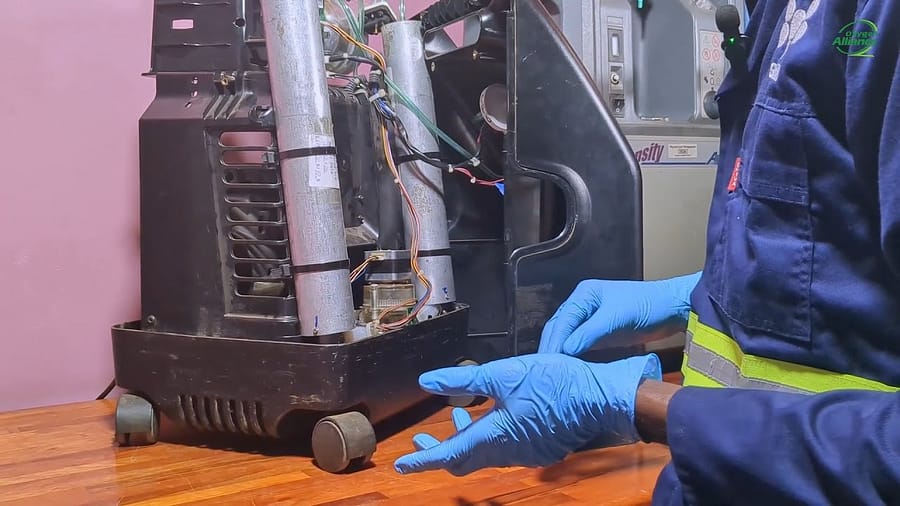

Medical Gas Systems work around the clock to provide essential gases like oxygen, nitrous oxide, carbon dioxide, etc., to the patients in the healthcare facility via pipelines. Therefore, considering the perpetual functionality of medical gas systems in hospitals, they must be well-maintained and repaired promptly. However, some risks associated with the maintenance of medical gas systems can result in catastrophic effects.

Some of these problems that hinder the maintenance of the medical gas system are as follows:

- DESIGN STAGE

- Cost-effectiveness over maintenance: When healthcare facilities are being planned and the initial design for the medical gas system is laid out, the primary focus becomes cost-effectiveness rather than long-term maintenance. This causes the biggest problem in maintaining the medical gas system in the later stages. These faulty designs account for high maintenance costs (1).

If the maintenance issues are addressed early at the design stage, it will save a lot of resources in the future, including cost, human power, and time. Therefore, effective designs should always consider the processes required to minimize errors and maintenance needs throughout their lifecycle (2).

- Communication gap: Another issue faced during the planning stage is the lack of proper communication between healthcare facility designers and facility managers. The designers must take feedback from facility managers about design-caused maintenance issues, which will improve design outputs (3). Moreover, lifecycle costs can be effectively reduced with improved operational continuity.

- Lack of future expansion consideration: It is one of the common concerns that healthcare facilities have previously faced is expansion consideration. If, at the design stage, the needs and requirements for future expansions are not realized and addressed adequately, it becomes extremely problematic to implement them. Multiple cuttings of the pipelines at various points can lead to a shutdown of the whole or part of the system and the risk of contamination. This could have been avoided if the designers had considered future expansion while planning the initial design.

- CONSTRUCTION STAGE

- Faulty designs: Some issues may arise during the construction phase as well. Operational effectiveness can be affected by the designer’s decisions, such as shutdown schemes in healthcare facilities. For example, the layout of valves will cause operations to shut down, affecting the effectiveness of the whole system.

- Unexpected improvisations: Some cases reported limited ceiling space, which hindered maintenance as well as the expansion process. More such issues caused construction crews to improvise and led to incorrect follow-ups on the design plan. One of these examples is the cross-connection of gases, which can cause serious destructive effects, considering mixing up of gases can be hazardous to human health (3, 4).

- MANAGEMENT STAGE

- Economical burden: During the management stage of the medical gas system, multiple errors can occur either due to faulty design, which sometimes stay hidden until they are operated, or due to any technical issues. Therefore, maintenance and repair of such issues should be done in a timely manner. High maintenance expenditures, a smaller budget, and urgent operationalizations can adversely affect the maintenance process.

Considering the above mentioned issues, it is better to stick to the guidelines and communicate well with experienced healthcare facility managers, especially at the design stage, so future operating costs, expansions, and maintenance processes can be made economical, possible, and easier.