Introduction and Initial Assessment

A report of low oxygen purity represents a critical failure in the core function of an oxygen concentrator. Resolving this issue requires a systematic diagnostic approach that moves from common external faults to complex internal system failures. This protocol provides a clear diagnostic path for the service professional.

Safety Precautions

As per industry best practice, disconnect the device from the power source before removing covers for internal service. Be aware that oxygen concentrators create an oxygen-enriched environment; adhere to all fire safety protocols. This protocol requires the inspection of electronic components; follow all electrostatic discharge (ESD) safety procedures.

Tier 1 Diagnosis: Low Oxygen Purity via Airflow Restriction

The investigation begins with the most common cause of poor performance: restricted airflow.

- Action: Systematically inspect, clean, and, if necessary, replace the cabinet and compressor intake filters.

- Rationale: Filters clogged with dust and debris will starve the compressor of the air required to generate adequate pressure for the pressure swing absorption process.

Tier 2 Diagnosis: Control Valve Function

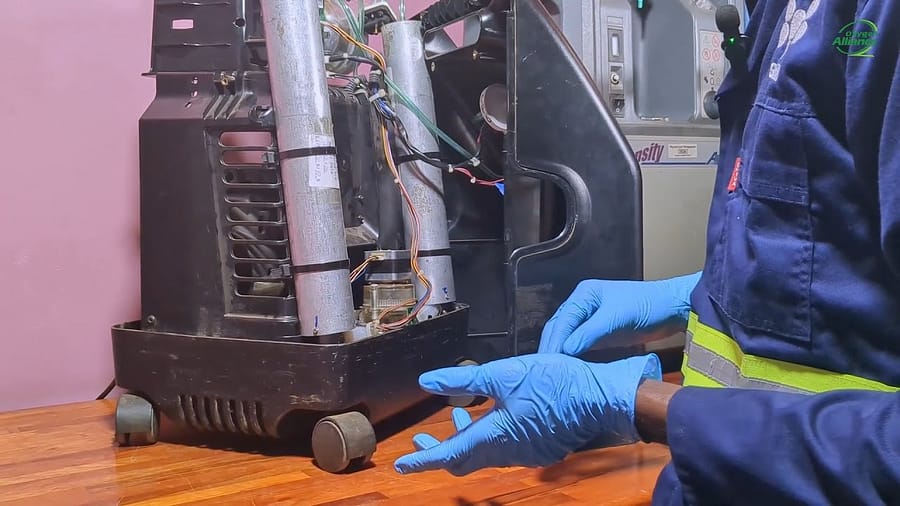

If filters are confirmed to be clear, the investigation moves to the control valve, also known as the four-way or rotary valve. This component directs airflow between the compressor, sieve beds, and exhaust.

- Action 3.1 (Mechanical): Observe the control valve for correct mechanical action. A failure can manifest as a valve that stops rotating, as seen on a Dedi 525 unit.

- Action 3.2 (Electrical): Check the wire harness connecting the valve to the main board for a secure connection. Inspect for misaligned position sensors, such as a Hall effect sensor, that prevent the PCB from knowing the valve’s position.

Tier 3 Diagnosis: Printed Circuit Board (PCB) Faults

Should the control valve be functional, the final area of inquiry is the printed circuit board itself. A fault on the board can lead to a cascade of component failures.

- Action: Inspect the main board for on-board diagnostic indicators. On a New Life Intensity concentrator, for example, a series of LEDs corresponds to the different solenoid valves. If an LED fails to light up, it points directly to a problem in that specific circuit.

- Rationale: An inactive LED often indicates a failed component, such as a transistor, which prevents the associated valve from activating. This level of component diagnostics is the mark of a highly skilled technician.

Video Resource

A detailed video is available to provide a practical, visual guide through these advanced troubleshooting steps across different models of oxygen concentrators.

Watch the full troubleshooting video here: