Objective and Scope

The operational reliability of a high-capacity oxygen concentrator like the NewLife Intensity is directly tied to the performance of its core pneumatic components. The four-way feed/waste solenoid valve is arguably the most active and critical of these parts, orchestrating the entire oxygen generation cycle. Over time, internal contamination and wear can degrade its performance, leading to system failures. For the dedicated biomedical professional, possessing the skill to perform a complete overhaul of this valve is essential for maintaining these machines at their peak operational standard.

Required Tools and Safety Precautions

Required Tools

A full service of this valve requires specific tools.

- Shifting spanner

- Screwdrivers

Safety Precautions

Safety Warning As per industry best practice, ensure the oxygen concentrator is disconnected from the mains power source and the pneumatic system is fully depressurized before commencing service. Failure to do so may result in equipment damage or personal injury.

Service Procedure

A full service of the NewLife Intensity’s solenoid valve is a methodical process that requires careful attention to detail.

Disassembly

- The procedure begins with the systematic disassembly of the valve assembly. Using a shifting spanner and screwdrivers, remove the external pipes connecting the valve to the sieve beds, followed by the exhaust muffler and the main inlet pipe from the compressor.

- Once the external connections are clear, the valve itself can be taken apart. Slide the solenoid coils off.

- Disassemble the main valve body piece by piece. This reveals the internal components: the plungers, the springs, and the crucial O-rings that seal the internal chambers.

Cleaning and Inspection

- A key part of the service is a thorough cleaning of every component. The internal passages of the main valve block can accumulate a fine black dust over time, which is a byproduct of the normal wear of internal seals. This residue must be meticulously cleaned out, as it can cause the plungers to stick and the valve to malfunction.

- Each part, including the plungers and springs, is wiped clean.

- The O-rings are carefully inspected for any signs of cracking, brittleness, or damage.

Reassembly

- Any compromised O-ring must be replaced to prevent internal leaks, which are a primary cause of low oxygen purity.

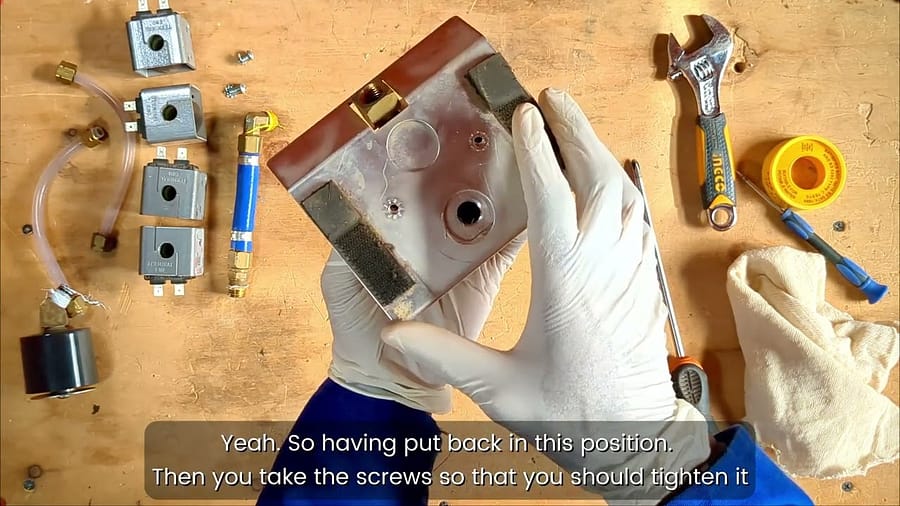

- Reassemble the valve in the reverse order of disassembly, ensuring all new and existing components are seated correctly.

Conclusion: The Value of Component-Level Restoration

Mastering the complete service of this valve provides a significant advantage in troubleshooting and repair. It allows a technician to perform a detailed, component-level restoration instead of being limited to simply replacing an entire expensive valve assembly. This level of technical skill demonstrates a deep understanding of the equipment’s mechanics and a commitment to cost-effective, high-quality maintenance.

Video Resource

To provide a clear and detailed visual guide for this procedure, a video has been produced that shows the entire process from start to finish. The video shows a technician performing a complete disassembly, thorough cleaning, and careful reassembly of the NewLife Intensity solenoid valve.

Watch the full service video here: